| 1. Fine cut parts (with no die-roll, no die-break, very little burr) | |

|

|

|

|

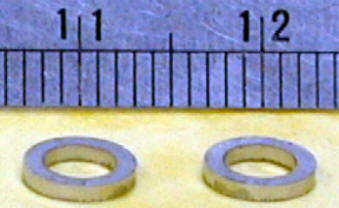

A fine cut magnetic part. |

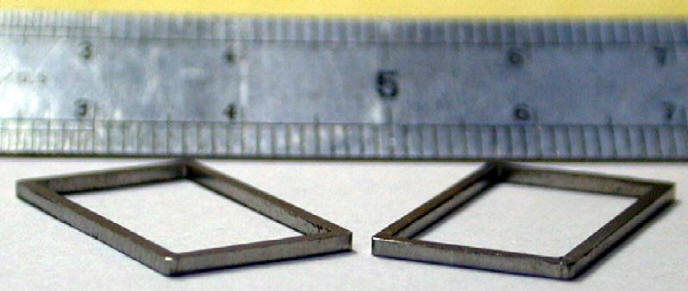

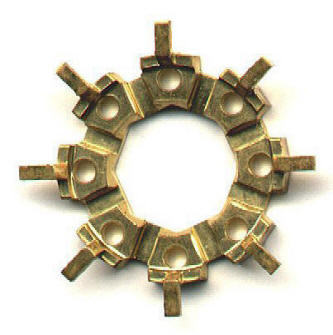

A part for a photocopy machine. Ring forging and outer cutting are complex. The original thickness of the material was 4.8mm and the narrowest portion was 0.9mm. |

|

|

|

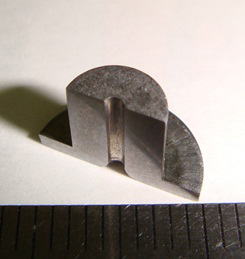

A small pressed hole(1.2mm Dia./6.0mm thickness) |

|

A small pressed hole(1.2mm Dia./7.2mm thickness) |

|